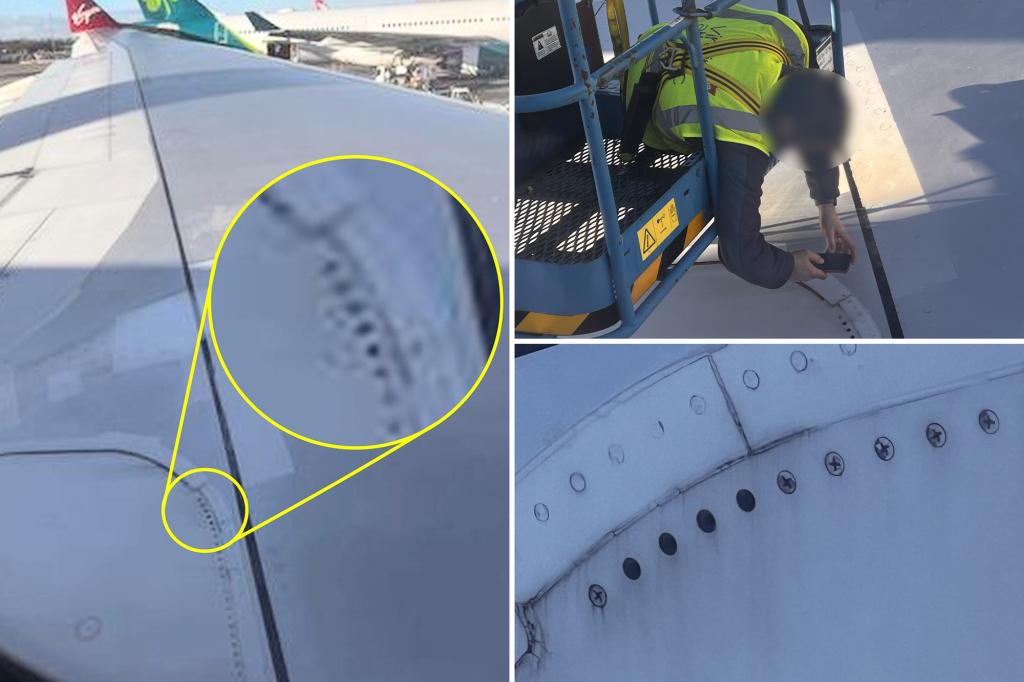

A New York-bound Virgin Atlantic flight was canceled just moments before takeoff last week when an alarmed passenger said he spotted several screws missing from the plane’s wing.

New York Post is a right wing shitrag like The Daily Mail.

What do you think the implications of that are for this article reporting a completely non-political incident?

They get traffic and unless someone comments otherwise, a slight boost in perceived respectability

Probably that they generally don’t care about getting a story right or corroborating sources. I agree that in this case that doesn’t matter for getting the high level facts across.

Everything is political, at least with them.

Stealing catalitic converters for moneyStealing bigass phillips screws from planes

–petty theift criminals

The pilot should’ve walked out onto the wing, slapped a couple lengths of duct tape on that section, then carefully and loudly exclaimed; “ YUP! That baby ain’t goin’ anywhere.” while patting the area firmly.

It’s called speed tape, and genuinely is a thing used in the industry.

I sympathise with the airline because it’s always a pain when you’ve nearly completed the flatpack before you realise that one screw is missing. Hopefully it’ll hold together without it.

you can’t just screwdriver those things in there man you have to torque them in to the proper spec holy balls

I think they were checking how loose the others were rather than tightening them.

Well they are Phillips has so I can’t imagine you can even torque them that much.

Interestingly enough they are not Phillips it is a very similar looking standard called Torq-set. The lines of the cross are off set a little which make it much easier to put a higher torque into them.

https://en.m.wikipedia.org/wiki/List_of_screw_drives#/media/File%3AScrew_Head_-_Torq-set.svg

Is there any advantage to those over square (Robertson)? I still see 4 contact points when applying torque. So about on par with square and inferior to 6-lobed torx.

Well… It comes down to what material is used, as well as requirements and geometry for the screw.

I love Robertson, but with enough over-torque, you shear the head off the threads or worse, round the hole if there isn’t enough rigid material around the square hole.

Failure modes are: stretching the material outwards until the bit slips. For the torq-set, you would need to shear the screw head material in front of each of the driver’s tips off and out, much less likely than shearing the head off the threads, or shearing the bit itself.

Both have the great feature that screws placed on the head stay in place, making installation much easier.

Aerodynamically, the torq-set has a much smaller ‘opening’ than does Robertson or torx.

Engineering is all about solving a problem in a quality way now, and ideally, considering issues for the future. A downside could be ice/grit getting stuck inside the smaller opening, as an example.

At some point, that part was taken off the plane and it was replaced, or maintenance was done on it, or maintenance was done on something underneath it. It was then replaced. There is a documentation trail that says all of this was fully completed. The documentation was signed off on by someone who was qualified in this task, and/ or by a supervisor who checked it off.

If there is no documentation, or if the documentation indicates something was done that was in fact not done, the CAA/ FAA is going to have a big problem with this. They are sort of interested in how maintenance is done and documented. If they didn’t do this right, what else are they/ have they been “pencil whipping?”

I can see a pretty thorough inspection of their maintenance practices and documentation in the near future. If they find a pattern of this, the maintenance gets decertified and the airline can’t fly until they are cleared.

TL;DR Someone dun goofed

There’s a massive failure in maintenance and Operations’ culture here. This isn’t the exact sort of situation where you’d use LOTO, but you need something similar. Lock the engine in the off position until the removed part is properly reinstalled.

I want to call maintenance errors like this rookie… But they really aren’t. There’s plenty of plant incidents where people either don’t have a proper procedure or don’t follow it, and a welder tries to work on a live gas line. Or someone opens a valve without realizing it needs to be closed.

I still say we fine the companies and hold the CEOs personally responsible, because the buck stops there, and these mistakes are more likely to happen in an organization that doesn’t have a robust safety culture.

Seeing how disorganized and chaotic airports are, I’m not surprised.

Lol, “the Virgin Representative”

Given how completely the airline industry disregards customer service and treats its customers like cattle, I don’t know why anyone would expect them to do a proper job of maintaining equipment. Furthermore, given how eager we are to gut regulation and dismantle the administrative state, all of this is going to just keep getting worse and worse.

“b-b-but taxes are theft!”

/s

We’re going to have to start walking around the plane with the pilot before takeoff like a rental car dent check.

NY Post? Be serious, don’t post that drama rag here.

So lucky they spotted it. Really makes you think, wouldn’t it be good to implement a system of regular professional inspections to deal with stuff like that? /s

Regular Inspections fix small issues before greater problems arise from them –> some economist with no technical knowledge or common sense goes: hurp de durp our inspections never fix any relevant defects. Better cut back on them to be more economic. –> surprisedPikachu.jpeg

Regular inspections are already mandate by the FAA, no economist, accountant or MBA has any say on it.

Well no. Those are the accountants. Economists have studied survivorship bias. It’s the MBAs and accountants looking to cut costs that do that stupid shit.

Speed holes

I knew software companies were offloading QA testing onto their paying users, but who would have guessed that passengers would start playing that role too?

Early Access Airplane

Some big wig had to go to target one day and saw the self checkout line and was like “I have an idea!”

deleted by creator

In return, he had a conversation with a big wig from Target where he taught them how many checkout stations you could actually cram into a tiny space.