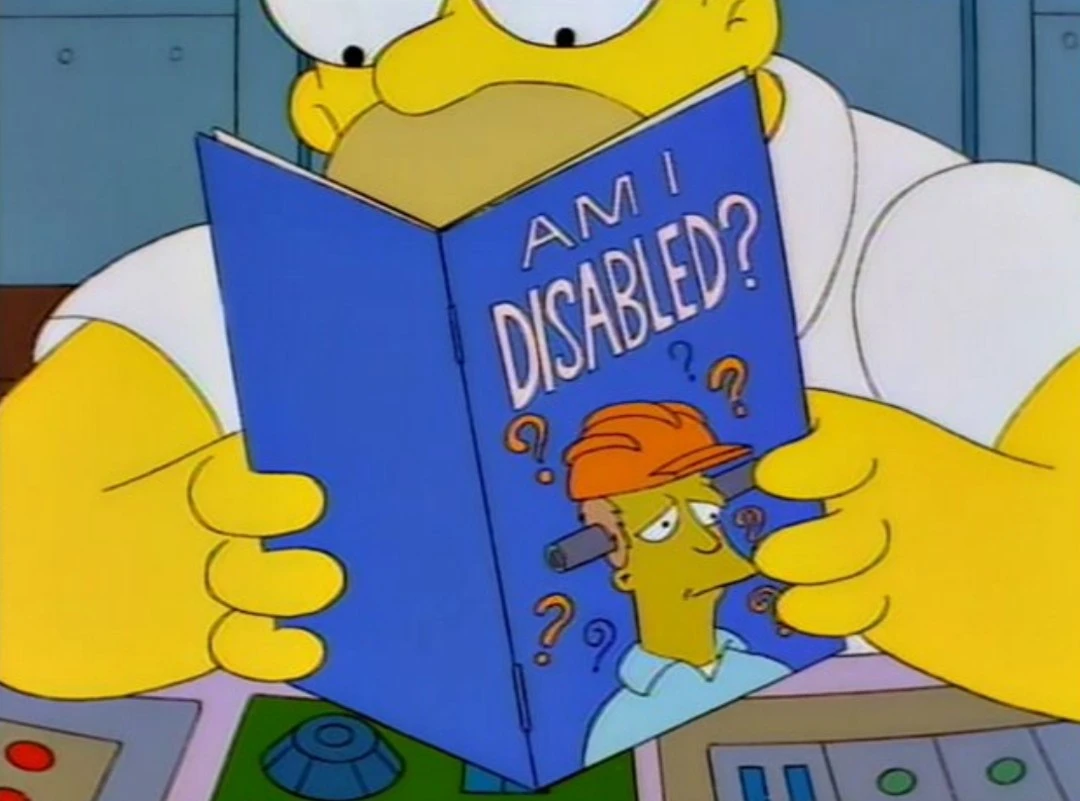

Tesla is facing issues with the bare metal construction of the Cybertruck, which Elon Musk warned was as tricky to do as making Lego bricks

Wait, I thought he was just bullshitting his fans with that. He’s actually serious? XD

Also, I don’t understand what this has to do with bare metal construction of the Cybertruck and why that should present exceptional difficulties. DeLorean figured out how to make bare metal cars more than forty years ago, so it can’t be that hard.

That’s an idea I would have supported when I was taking high school physics. My astronomy calculations I put to the nearest centimetre (something like 20 significant digits sometimes) for no good reason. Just writing down all the numbers from the calculator.

Then I took engineering and grew out of it. Sure some crucial parts need very tight tolerancing, but you also have to have it relative to the size of the part. And if your design is bad, better tolerancing isn’t going to save you from stuff like the steering wheel popping out.

My grandpa once published an article where he turned a tree circumference (obtained using a tape measure) into a “diameter estimate” with 6 significant figures. Turns out, he was wrong on the 4th digit because he used π=3.14…

The difference between accuracy and precision.

My high-school chemistry teacher would dock a point for each extra digit past the calculation’s actual precision. We learned quickly not to overstate our sig figs.

An answer written as “3” means that the true value is somewhere between 2½ and 3½. If you write “3.19142” when what you actually know is “3”, you’re incorrectly excluding the vast majority of the possible true values.

Our physics teacher taught measurements and uncertainties as the very first thing in our multi-year syllabus. All answers thereafter needed to be in the precision implied from the number of significant figures in the given figures and error propagation.

Yeah it’s one thing to spit out numbers. But as an engineer I have to understand what’s going to happen with thermal expansion, wear and tear, and what can actually be produced consistently by an apathetic worker on their 60th hour of work that week

Wait until you hear about what CS does to run-time complexity. Throw away the constants and small factors, nobody cares!

Just writing down all the numbers from the calculator.

Please tell me you actually had that many digits of significant figures and weren’t just copying down overly-specific figures from your calculator…

Prof here…it’s always the latter.

He most certainly didn’t. Other than physical constants, very few measurements were ever taken to more than 15 significant figures. It’s just not practical as no instrument will get 1m precision over a light year. A spacecraft travelling anywhere near that far will just get an order of magnitude closer and then recalculate with one more digit of precision.

You are exactly right, and I wasn’t copy pasting I was writing it all down as part of pen-and-paper submitted answers. I don’t have 1/5 of the energy for such trivial things anymore.

Due to the nature of Cybertruck, which is made of bright metal with mostly straight edges, any dimensional variation shows up like a sore thumb.

It sounds to me like the reasonable conclusion to draw from this would be to modify the design of the car. I’d also assume you don’t need tolerances to be the same for literally all parts inside and out. I’d also think that, if the car looks that bad if things are 10 or more microns out of place, these cars are going to age terribly after regular use.

But what do I know? If I were smart, I’d be rich, right? And Elon is so rich, he must be a genius!

The awkward moment where you sit on the car watching the sunset with your sweetheart and the next day your stainless steel car is bent.

Tesla is know for shoddy panel alignment correct? This is gonna look horrific.

They are, and that undoubtedly gets under his sub micron thick skin, which is why he’s going overboard about it with this.

Yeah heat that mf up on a sunny day vs a cold day lol what an idiot.

It’s not like “accuracies” doesn’t add up either ha ha what a genius.

Usually car makers solve the expansion and contraction using glue, curves, and trim to deal with expansion and contraction.

The cybertruck has no curves and not much trim, the glue would have to be very flexible, which would lead to separation.

I am going to bet that we will see cybertruck with panels flying off or flapping at highway speeds not long after release.

Oh yes, I’m all with you here, either make a frame and stick the “panels” to it individually (probably good if you make a cheap tank vehicle or something IDK) or make a chassis that take the deformation forces and distribute them as evenly as possible.

My bet is they have him as a stupid publicity monkey drawing attention to Tesla, cybortryck etc (I mean all publicity is good right?) and away from bad things like Tesla didnt self drive end 2019(?) and still doesn’t, child labour, … etc

High accuracy, low precision.

deleted by creator

These tolerances are very possible to hold while machining, but speaking from my perspective having been a machinist by trade for 20+ years, holding those tolerances for every single part on a vehicle is going to get prohibitively expensive really fucking fast.

Micron, as in 0.00004"? Yes you COULD hold it, with second ops and temp control.

The article states “sub 10 micron”, which I interpreted to be +/- .0004" in practice

The total tolerance is .0004". In equally disposed bilateral tolerancing it will be ±.0002".

Eh, if someone tells me to reduce a tolerance from 5 to 10 thou at work, it’s understood that it’s +/-5 and 10. I don’t think I’ve ever heard someone use the full range of a tolerance in conversation. If the tolerance isn’t bilateral, it would be said like plus 5, minus zero. Anyways, +/- .0005" is our standard tolerance on the span of all dowel hole pairs.

Bilateral tolerancing is a Machinist’s first introduction to tolerancing so it’s no surprise to run that as default. And I suppose GD&T is not heavily used where you are.

If you’re given a parallelism tolerance of 10 micron are you assuming that to be ±10 micron? True position? Angularity of 5 thou? Etc… The only feature control that could be interpreted as bilateral by default is profile and it’s still communicated by its total tolerance.

Simple ± tolerancing isn’t the industry standard anymore. And if Tesla prints are anything like spaceX ones… It’s basically all GD&T and minimal title block tolerances.

I use GD&T on all my drawings, including 100% of my hole callouts. However I’m one of the more enthusiastic adopters of ASME Y14.5 at the place I work. Therefore, I get what your saying regarding the tolerance range, but since most of my coworkers are still relying on block tolerances, I’ll refer to a .010" positional tolerance as a “+/- .005” equivalent" in conversation so there is no miscommunication. I can see how this is not the norm.

On the dowel hole point, just measuring this stuff is going to take at the bare minimum an automated and purpose built CMM, which will drive the cost up even more. If we are to assume +/- 5 microns for every single part - we are talking about the level of manufacturing that Mitutoyo or Starrett have. This will be a multi-million dollar vehicle that noone would buy.

Just curious… what does Starrett have that Tesla will need?

Starrett isn’t known for quality precision metrology.

Well, in terms of for real metrology, you are correct. A better comparison would have been Brown and Sharpe. However, Starrett has more than enough reputation of everything that they produce being of a very high standard- primarily layout tools like calipers, precision levels, etc.

ETA: This could very well be my bias as an American showing. I know from experience that the fit and finish of a high end pair of Mitutoyo calipers have what I consider to be subpar to the Starrett equivalent in terms of fit and finish. There is also a $500 ish price difference which could also be a subconscious bias.

Elon: “Stacking” tolerances? No, we will not tolerate anything less than micron precision on every aspect of the design.

He’s probably hyper self conscious about people ripping into Teslas over their clearances (with inconsistencies measured in millimetres). But, no, instead of saying “VW can produce stuff that doesn’t look like it fell from a truck and you will figure it out, too” he’s going overboard.

If we’re going overboard, why bother with cars at all? Just use this cheesy blueprint, make it work and solve all of humanity’s problems! This is what California should invest in instead of trains.

Basically, it’s an admission that the cybertruck is going to stand out like a sore thumb due to normal wear and tear.

“Bad news guys… We’re gonna have to delay production for just TWO MORE YEARS because of these woke microns! The good news though, you can get re-premium upgraded waitlist VIP positioning with a renewal deposit of only $500”

It’s just marketing. Elon wants dumb tesla bros to think their truck is built to that accuracy. No need for it to be reality.

In the full email he goes on to tell the engineer what a micron is.

I guess, he just read that word somewhere and now feels cool that he knows it.

It would be cute if he was a junior manager, but this way it’s just sad.

You really think he wrote it? He has an army of engineers working for him, many of which would kill their mothers to get on Elon’s good side, corporate culture is same shit different smell no matter the corporation.

The leaked email has his name on it and the leak claims it was an email from Elon to employees. Can’t really tell if the leak is real or fake, but if it’s real then Elon is definitely the one who wrote it.

Based on his proclivity to say dumb shit and his inability to keep his mouth shut, I’m inclined to believe it’s a real leak.

This 100% sounds like him. I don’t see any reason to doubt it given that if someone was going to make something up it wouldn’t sound like this.

If LEGO and soda cans, which are very low cost, can do this, so can we.

This man is a certifiable idiot, and I feel bad for anyone working for him.

I mean, to be fair, he’s not entirely wrong, you can get that accuracy on larger parts given sufficient time, materials, tools, expertise, etc.

But a car has more parts than a Lego brick

Which will balloon the cost exponentially.

Maybe he can build the truck out of LEGOs - it would cost about a bajillion dollars to make something that size, but maybe less than the parts he’s demanding would be.

Yeah anything is possible with enough time and money, it’s just that is about the most textbook example of comparing apples to oranges I’ve seen IRL.

Also, I suppose Lego bricks might be considered low cost if you’re a billionaire, but in the grand scheme of molded plastics they are very much a premium product.

Yeah compared to car plastics they’re crazy expensive

What happens when you put that large metal part in the sun? He is entirely wrong.

Well, of course. It doesn’t change my statement though.

And the guys down the lab could go “well, we don’t have to make it out of metal.” And then it starts a rabbit hole of further insane requests that are technically possible, but to people unfamiliar with engineering (Elon) say “damn the cost” betting (incorrectly) that the time or financial cost to fulfill the requests is still profitable.

Happens to a lot of products, unfortunately. People making demands are better off knowing what the demand entails. When they do not, this is what we get.

He’s also probably confusing his experience with Space-X too. He can’t think critically, and it’s going to be his undoing. I hope at least.

Two things, not necessarily related.

-

The cybertronk looks highly regarded when put together correctly. Imagine if it has the panel gaps of other cars TSLA makes.

-

My tinfoil hat theory on why Elon is acting all right wing all of the sudden is to get those idiots to buy electric bare metal Pontiac Aztecs with “unbreakable” windows instead of F-150’s

-

10 microns is .4 thou, about the width of a cotton fiber. Its possible to machine those tolerances, but very time consuming as machine maintainance steps up. Its also small enough that the thermal expansion of the sheets will be larger than that

deleted by creator

Thanks, I understand my error now. Corrected

deleted by creator

Isn’t that 10 microns? 0.01mm?

Which is 0.4 thou

Oh haha, yeah, I understand my error now. Thanks for bearing with me

0.4 thou = 0.4 mil

(TIL about thous, all my engineering textbooks referencing US units must be old or something)

decimal inches is basically only used in machining. The only time ive ever seen it is in schematics and an indicators.

Imagine measuring door panels on a granite block in a climate controlled room, and sending it off to the surface grinder for rework. 🤣 Or sending the frame off to get scraped. Truly, this is the most idiotic idea on the planet and it’s all because he didn’t care about tolerances early on. His self own has turned into whatever the hell this crap was.

I can confirm this

Machinist here.

.004 ? That is exagerated but .0004 this is insane

This is not a airplane engine !!!

Which just shows he has no idea how tolerances work. Small machined parts have different tolerances than large stamped parts. The key is setting the right tolerances for each part, designing the vehicle for desired gaps with those tolerances, and continuous improvement to fix and design out issues.

None at all. He also doesn’t understend that the issues tesla has faced are largely due to poor process design rather than automotive design. The plans may call for small gaps ore big gaps, but they certainly don’t call for iconsistent gaps

So basically elon would rather dump money into expensive equipment to improve build quality than do the thing that’s actually needed to improve build quality and pay his workers what their work is worth and make their factory environment safer?

This is the kind of petty angry bullshit you have to do to be a billionaire. Its not about being smart, it’s about on some level hating everyone that isn’t you

What I meant is that Elon has set a fairly un-achievable standard, as the sheet metal parts he is talking about will grow and shrink by more than that depending on weather. Additionaly, the small parts can be machined to that tolerance, but only by a skilled machinist and not at assembly line levels.

Besides just thermal expansion, which will totally happen by driving on the road, the rotation of the motors and the use of brakes.

It will also flex as it hits bumps and takes turns.

And these will be different metals. With different thicknesses which will expand and contract at different rates.

Making a lot of assumptions about what he’s willing to put into this.

He’s not going to get fancy expensive new equipment, he’s not going to hire the best machinists, he’s not going to slow the work down to allow that kind of accuracy. He’s going to bluster and shout and make demands without providing any way of actually achieving those demands. That’s what Elon does. He’s not an Engineer, he doesn’t design things, he doesn’t build things, he tells people who actually know what they’re doing to build something. Here, he’s just saying “Do better” without anything more, and expecting that to be enough because he doesn’t actually know shit about dick.

Frankly the closest I’ve seen to evidence that Elon has ever actually designed anything is the eyesore that is the Cybertruck, because it absolutely looks like something that cretin would draw in crayon and demand be made a reality.

Harsh, but fair 😂

Reminds me of Bill Burr https://youtu.be/E3s-qZsjK8I?si=YKykzYsFt7lnPC6g

Here is an alternative Piped link(s): https://piped.video/E3s-qZsjK8I?si=YKykzYsFt7lnPC6g

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I’m open-source, check me out at GitHub.

Lol, never saw that bit before. Bill Burr is an absolute treasure.

I love the uncomfortable silence. He makes really good use of it too. I’ve seen him do that several times and it’s always hilarious to me.

It’s design demonstrates a fundamental misunderstanding of what trucks are for. I know people give the CEO of Ford shit for saying hes not worried about the Cybertruck because people who want to do real work wouldn’t take any interest in it, but its true. Trucks all have the shape of bed they do for a reason. Convergent product evolution landed on that as the best shape for a bed for trailer hitches

Actually, anyone else notice how comically small most truck beds are nowadays? So embarrassing.

Oh you mean those SUVs with the open-air trunks?

Very true, and very annoying. Anytime I see thst all I can think is that its a family sedan for someone not confident enouf in their manhood

Also for shitty drivers. Many people buy large trucks so they don’t have to drive decently.

And then they don’t know where the front end of their vehicle is, making the roads more dangerous for everyone

I mean… I literally bought a Ford Maverick because it was like a four door family car with the added bonus of a truck bed for many of the purposes I would have wanted a truck for.

Maverick gets a pass for being a small hybrid rather than a gas guzzling 1500 with no torque

This is the very first thing I thought of when I saw cybertruck

You aren’t going to hit that tolerance consistently on an assembly line no matter how much you pay. Can be done by a skilled machinist, but there are too many dynamical variables in an assembly line environment, like the previously mentioned thermal expansion.

deleted by creator

It’s not even about that. You absolutely don’t need those tolerances for a cup holder. An assembly line will fuck it up regardless. You use tolerances like that when needed - in jet engines or turbines. Insisting on those numbers on a car is plain stupid - it isn’t better (other than the ego boosting “my car has high tolerances where nobody cares”) than just doing it like every other manufacturer does it. It’s a waste of money plain and simple.

For reference, in working with parts that interface directly with optical components about the tightest I’m ever comfortable specifying at production volumes is 0.05mm and that is for very specific dimensions and not entire parts yet he is demanding 5 times lower tolerances here.

There are companies making bricks in much better quality than LEGO, and they are cheaper than LEGO. What kind of a margin is this supposed to be?

I seriously doubt it. People buy LEGO because the alternatives are shit and they don’t know how to accurately manufacture them.

Yeah maybe 5 years ago. Just get any brand using GoBricks and it’s 99,99% there

My guy, you can’t drop these claims without telling us who! Lego are so expensive, I’d love some supposedly higher quality alternatives.

Apologies, I would recommend checking out https://www.bluebrixx.com/en/ to get an impression of what other vendors offer. You can look up the brands and models on your local Amazon, Alibaba, your local brick dealer, … These prices are a lot lower that LEGO sets, so you might be able to try different vendors and see what’s on the market.

My homemade 3D printer that makes one of these rackus just because it’s not very good can make lego tolerance. It can’t cut metal though so I don’t know wtf he’s dreaming about lol.

Im a lego enthusiast and. having Lego brick is a bragging right !!!

I know, and I have loved Lego since getting that 8880 for Christmas that one year! But that is in the past, and spending 500€ on a LEGO set, when I can get a much more enjoyable experience from another vendor at a fraction of the cost, just doesn’t feel right to me these days. But to each their own, and I still love the LEGO sets I do have.

Keeep it till your retirement !!!

Doubt.

cheaper than lego

I’m listening. Please do share.

I have a Mould King 13112 RC Excavator. All parts are on par and compatible with Lego bricks. Excellent quality, a bit tighter fit than regular Lego and the model itself is way more interesting and fun to build than anything Lego has produced in the Technic line in the past years. On top it is much cheaper than a comparable Lego set and it has an excellent building manual.

Mould King sounds like a Dark Souls/Elden Ring character.

My kid got a non Lego set as a gift and what a letdown that was. It’s a frustrating excersise as the construction simply doesn’t holds up like the real thing.

We had to give up building the damn thing.

Yeah, the tolerances are looser so it doesn’t click into place and stay in place easily. The plastic is less rigid and more pliable, making fitting even more difficult. The colors also fade more quickly.

Exactly, this makes them not worth it.

Any brands you would recommend?

I usually shop around on https://www.bluebrixx.com/en/ Their Specials didn’t disappoint so far. They carry other vendors too, but you might want to browse reviews on the web to see what’s really good. Quality does vary between vendors, but LEGO bricks aren’t as perfect as people believe either.

Bluebrix is nice

Try looking for Mould King or Cada - those are usually the ones that are considered to deliver great quality for a reasonable price.

It should be mentioned that both companies are gearing their products much more towards an older audience - so they aren’t really an alternative when talking about kids playsets.

Yes like guns ! Lego wont make sets that oriented to violence or wqr

Cada make nice plastic guns !!!

Hilarious considering the panel gaps in all his other cars, dude is fucking insane. Unattainable standards don’t breed better work they breed exasperation and apathy.