Well I guess the era of nanobots isn’t far then

Aww it’s a bebe!

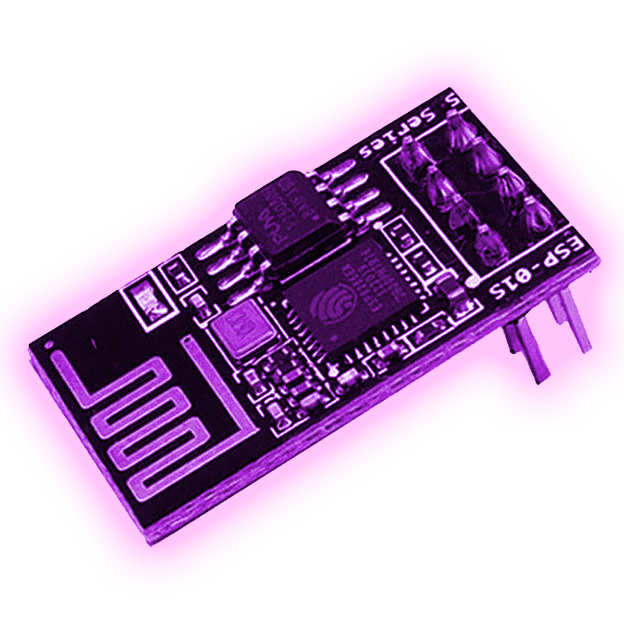

That looks like a real pain in the ass to solder with a 0.35mm pin pitch.

Not something I would try to hand-solder. Not something that feels relevant for me as a hobbyist either, although it’s very cool.

I’m a few months late, but I actually recommend people try to solder these at home at a hobbyist.

Below a certain size, you rely upon surface tension of the solder to “pull” the components into place. Its a combination of solder-mask (by your PCB-manufacturer) + well calibrated PCB Software + proper heating technique (hotplate and/or oven).

You’ll be surprised how “far” lead will pull your components into the correct spot. In fact, the force is so powerful that smaller components can tombstone if one side melts before the other side (ex: cold joint due to more copper pour melts slightly after, causing the “hot” side to YANK the component so hard it “flips up”).

VQFN packages are “square” though, so its unlikely for them to tombstone.

Imagine the arduino-clone boards with these… For very small hands!

Most embeddable medical devices need wireless to share out data and get OTA updates. Unless you’re doing wired things, in which case MCU size may not matter.

As cool as the TI is, I’d look at the new SiLabs BG29 for processing + BLE: https://news.silabs.com/2025-03-12-Silicon-Labs-Unveils-BG29-The-Future-of-Bluetooth-R-LE-in-Miniature-Devices

On second thought… a medical device that goes in one end, collects data, and comes out the other end. OK, that may not need wireless… and it better be small.